BEST PICK FROM PROJECT PORTFOLIO

AUTO CHUTE SYSTEM

An automatic glove sorting system is a machine that sorts different sizes of gloves, often for packaging, using automated processes to reduce manual labor and increase efficiency.

AIR DRYING SYSTEM

An air knife drying system uses a focused, high-velocity stream of air to remove moisture, debris, and other contaminants from former surfaces, including gloves.

ROOF DOLLY AND TABLE TRANSFER

Roof dolly and table transfer is a system designed to automate the process of transferring car roofs, often used in automotive manufacturing or assembly lines.

SHOWER DRIZZLE

A rain or shower test booth, is used to simulate heavy rainfall conditions to assess a vehicle’s water tightness and identify potential leaks before they reach consumers. These machines are crucial for ensuring that vehicles meet quality standards and are resistant to water ingress in various weather conditions.

ACID CLEANING MACHINE

Acid cleaning machine is used in the glove manufacturing process to clean ceramic molds (formers) using an acid solution. This automated system removes calcium carbonate, latex residue, and other inorganic deposits, ensuring consistent cleaning and improving glove production efficiency.

SCRAP CONVEYOR

Scrap conveyors are crucial for efficiently and safely moving metal scrap generated during the stamping process. These conveyors, often made of durable steel belts, transport loose materials like offcuts and waste from presses to central baling locations. This automation reduces manual handling, minimizes safety risks associated with heavy lifting and sharp materials, and streamlines the scrap removal process, allowing for increased production efficiency.

AUTO MISSED-GLOVE COLLECTION SYSTEM

Auto missed-glove collection system designed to retrieve gloves that have been missed during the manufacturing process, often after a stacking or dipping process. These machines are crucial for maintaining production efficiency and minimizing waste by ensuring that all gloves are properly handled.

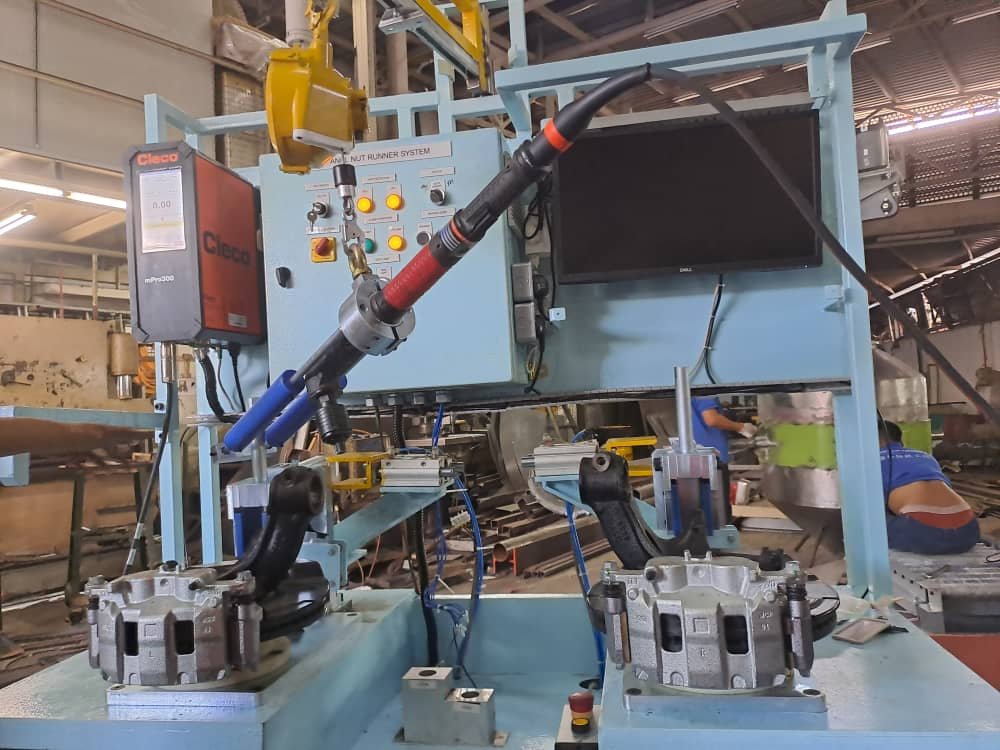

NEW TABLE JIG FOR NUT RUNER KNUCKLE MODULE

Nut runner knuckle module working station is where operators tighten the lug nuts on a brake, securing it to the brake disc and hub. The process involves using a torque wrench to ensure the nuts are tightened to the manufacturer’s specified torque, preventing loosening or damage to the studs and brake components.

AUTOMOTIVE DARKROOM

An automotive darkroom is a light-tight space designed for testing and evaluating vehicle components, particularly those related to lighting and visibility. It’s a controlled environment where researchers can simulate various nighttime driving conditions and assess factors like light distribution, glare, and driver visibility.